How to select the turning device of pipe chain conveyor accessories?

Pipe chain machine is also called pipe chain conveyor, pipe chain feeder and pipe chain elevator. The turning mechanism is a device to realize the stable turning of the pipe chain powder conveyor through a special structure, built-in bearings, sprockets and other auxiliary equipment, and through the contact and matching between sprockets and chains. The large turning angle is to turn and change the direction of the ring pipe body of the pipe chain powder conveyor directly according to the turning angle required by the equipment without additional turning device, which makes the equipment body form a large turning angle. Our company named it "large turning angle" according to its appearance and performance.

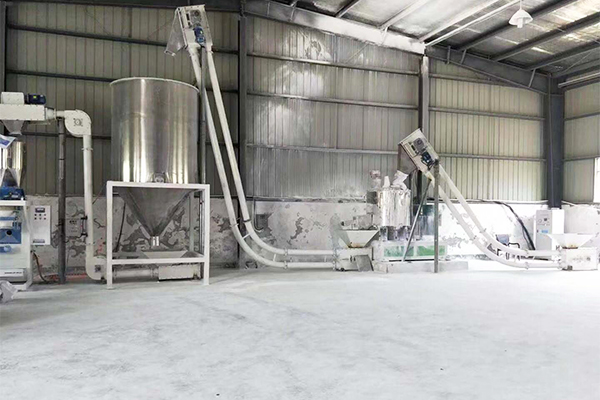

The turning chain pipe conveyor is a continuous conveying equipment for conveying powder, small particles and small pieces of bulk materials. In the closed pipeline, the chain is used as the transmission component to drive the animal materials along the pipeline. When conveying horizontally, the material particles are pushed by the chain in the moving direction. When the internal friction between the material layers is greater than the external friction between the material and the pipe wall, the material moves forward with the chain to form a stable material flow; During vertical transportation, the material particles in the pipe are pushed upward by the chain. Because the lower feeding prevents the upper material from sliding, resulting in transverse side pressure, the internal friction of the material is enhanced. When the internal friction between the materials is greater than the external friction between the material and the inner wall of the pipe and the self weight of the material, the material is transported upward with the chain to form a continuous material flow.

In modern society, many conveying equipment are also based on the conveying principle of waterwheel, and pipe chain conveyor is no exception. After numerous experimental improvements, the performance of pipe chain conveyor has greatly surpassed that of other conveying equipment. After understanding the operation principle of the pipe chain conveyor, many people will feel that its design principle is too simple. The whole conveying system is only inside the sealing ring pipe, the chain wheel drives the chain to rotate, and then the discs on the chain drive the materials to form a stable conveying material.

Although the pipe chain powder conveyor can continuously transport all kinds of powder materials. However, when the equipment structure needs to change direction and turn, the large angle and turning mechanism will not affect the material transportation. However, when the equipment transports some materials with strong adhesion and high moisture content, the use of turning mechanism will cause certain accumulation of materials here. However, this phenomenon does not cause equipment blockage, but it is inconvenient to clean up later when the materials become dry and hard. Therefore, at this time, we recommend the use of large corners for customers.

Generally, according to the different places of use, working environment, technical performance and types of transported materials of the belt conveyor, in order to meet a variety of working conditions, in addition to the commonly used chain pipe conveyor, there are a variety of special belt conveyors with new structures, among which the representative ones are: large inclination belt conveyor, Deep groove belt conveyor and belt pressing machine, tubular belt type, air cushion belt type, plane turning belt type, line friction type, corrugated edge retaining conveyor belt type transportation machinery, etc. there can be a variety of classification methods for refinement.